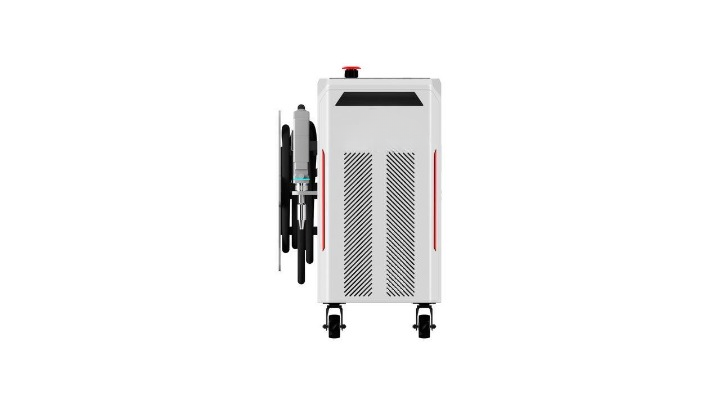

Air Cooled Handheld Laser Welder

Original price was: $8,499.00.$7,999.00Current price is: $7,999.00.

The VIVA 1200W Series Air Cooled Laser Welder offers powerful, precise welding for medium to heavy-duty metal fabrication

Power (W): 1200 W

Weldable Material: Carbon Steel, Stainless Steel, Aluminum, Galvanized Metal Plate, Copper

Welding Speed: 0–120 MM/S

Welding Thickness: 0.4 mm to 4 mm

Input Voltage: 220V

Total Power: 4000W

Gross Weight: 43 kgs

Out Carton Size: L:730 W:720 H:690 mm

Air Cooled Handheld Laser Welder: Revolutionizing Precision Welding

In the evolving landscape of metal fabrication, the demand for efficient, precise, and portable welding solutions is paramount. The Air Cooled Handheld Laser Welder emerges as a game-changer, offering unparalleled advantages for professionals seeking high-quality welds without the complexities of traditional systems.

Ideal Use Cases for 1200W:

The 1200W power output of the Air Cooled Handheld Laser Welder strikes the perfect balance between precision and strength. It’s powerful enough to handle medium to heavy-duty welding tasks, such as joining 2–4 mm thick stainless steel, carbon steel, aluminum, and galvanized sheet metal, while still offering the finesse needed for detailed, clean work.

This wattage makes it ideal for industries like automotive repair, equipment manufacturing, structural fabrication, and general metalwork, where both durability and appearance matter. Whether you’re sealing seams on metal cabinets or fabricating high-strength brackets, the 1200W configuration delivers consistent penetration and aesthetic finishes without the need for post-weld grinding.

The 1200W Air Cooled Laser Welder is perfect for light to medium welding tasks that require precision and clean results. With a welding thickness range of 0.4mm to 4mm, it’s great for:

-

Sheet metal fabrication

-

Signage and decorative metalwork

-

Electrical cabinets and appliance parts

-

Thin aluminum, stainless steel, and galvanized materials

-

Repair work and light manufacturing

It provides a solid mix of precision, power, and portability, making it an excellent choice for small workshops, mobile welders, and businesses working with thinner materials.

Understanding the Air Cooled Handheld Laser Welder

The Air Cooled Handheld Laser Welder is a state-of-the-art device designed for versatility and ease of use. Unlike traditional welding machines that rely on water cooling systems, this welder utilizes an advanced air cooling mechanism. This innovation not only reduces the machine’s footprint but also simplifies maintenance, making it an ideal choice for various applications.

Key Features and Benefits

1. Portability and Compact Design

One of the standout features of the VIVA Air Cooled Handheld Laser Welding Machine is its compact and lightweight design. Weighing approximately 43 kg and with dimensions of 730 mm x 720 mm x 690 mm, it is easily transportable, allowing professionals to perform on-site welding tasks with minimal setup time.

2. High Precision and Speed

Equipped with a 1200W power output, this welder delivers precise and clean welds on materials such as carbon steel, stainless steel, aluminum, and galvanized metals. With a welding speed ranging from 0 to 120 mm/s and the capability to handle material thicknesses between 0.4 mm to 4 mm, it ensures efficiency and accuracy in every task.

3. Energy Efficiency

Operating at a total power consumption of 4000W and requiring a 220V input voltage, the air cooled system is designed for energy efficiency. The absence of a water cooling system reduces power usage, leading to cost savings over time.

4. User-Friendly Interface

The welder features an intuitive interface, allowing users to adjust settings with ease. This user-centric design ensures that both seasoned professionals and newcomers can operate the machine effectively, reducing the learning curve associated with laser welding technology.

Applications Across Industries

The versatility of the VIVA air cooled handheld laser welding machine makes it suitable for a wide range of industries:

-

Automotive Industry: Ideal for repairing and fabricating car parts, ensuring strong and precise welds.

-

Construction: Useful for on-site welding tasks, providing flexibility and reducing downtime.

-

Manufacturing: Enhances production lines by delivering consistent and high-quality welds on various materials.

-

Aerospace: Meets the stringent requirements for precision and reliability in aerospace component fabrication.

Maintenance and Longevity

The air cooled system simplifies maintenance routines. Without the need for water cooling components, users can expect fewer mechanical issues and reduced maintenance costs. Regular cleaning and inspection of the air filters ensure optimal performance and extend the machine’s lifespan.

Safety Considerations

Safety is paramount in welding operations. This laser welding machine is designed with multiple safety features, including:

-

Emergency Stop Function: Allows immediate shutdown in case of emergencies.

-

Protective Housing: Shields users from laser emissions and mechanical parts.

-

Stable Base: Ensures the machine remains stationary during operation, preventing accidents.

Conclusion

The Air Cooled Handheld Laser Welder stands out as a reliable, efficient, and user-friendly solution for modern welding needs. Its combination of portability, precision, and energy efficiency makes it an invaluable tool across various industries. By integrating this advanced technology into your operations, you can achieve superior weld quality while optimizing productivity and reducing operational costs. Contact us today and let us provide you with our laser welding technology!

Reviews

There are no reviews yet.