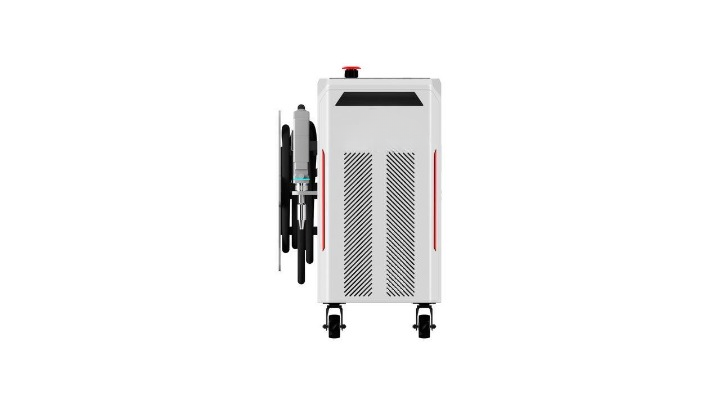

VIVA AIR COOLED LASER WELDING MACHINES

What are the benefits of purchasing the VIVA Air Cooled Laser Welding Machines?

Simple Setup & Portability

VIVA offers a compact and lightweight laser welding machine, making it easier to move and install. Ideal for mobile or on-site welding applications. No external chiller required, everything is integrated!

Lower Operating Costs

Eliminates the need for water cooling infrastructure such as chillers or pumps, all while reducing energy consumption. Less maintenance using an Air Cooled Laser Welder will ultimately lower long-term costs.

Consistant Performance

Efficient thermal management allows stable laser output and better weld quality over long working periods. Weld metal sheets, stainless steel, aluminum, and carbon steel in low to medium power applications.

What Makes The VIVA Air-Cooled Laser Welding Machines A Great Choice For Industrial Welding?

Air-cooled laser welding machines are an excellent choice for industrial welding due to their compact design, ease of use, and reliable performance. These machines come with built-in cooling systems that manage heat efficiently without requiring external components, making them incredibly user-friendly and quick to deploy. Their streamlined construction allows for greater mobility, making them ideal for both fixed workstations and on-site welding tasks. In addition, air-cooled welders are well-suited for continuous operation, offering consistent performance and long service life. They are perfect for industries that require precise, efficient, and clean welds on materials like stainless steel, aluminum, and carbon steel.

How Do The VIVA Air-Cooled Laser Welder Machines Help Reduce Maintenance and Downtime?

Air-cooled laser welding machines are designed with simplicity and reliability in mind, helping to minimize maintenance and reduce unexpected downtime. With fewer moving parts and no need for external cooling systems, these machines experience less wear and tear, which translates to fewer breakdowns and longer intervals between servicing. Their enclosed cooling system is easy to manage, with minimal maintenance requirements, making them ideal for busy production environments where uptime is critical. This efficiency not only improves workflow but also helps reduce long-term operational costs, making them a practical solution for any manufacturing setup.

Why Are The VIVA Air-Cooled Laser Welding Machines Ideal for Precision Metalwork?

Air-cooled laser welding machines are particularly well-suited for precision metalwork, thanks to their ability to deliver stable, high-quality welds. The built-in cooling system ensures the laser maintains a consistent temperature, which allows for uniform energy output and highly controlled welds. This is especially beneficial when working with thin metals or delicate components, where accuracy and control are essential. Many air-cooled models use advanced fiber laser technology, which enhances beam quality and results in clean, strong, and aesthetically pleasing welds. Whether for intricate parts, decorative finishes, or high-spec engineering, these machines deliver the accuracy professionals need.